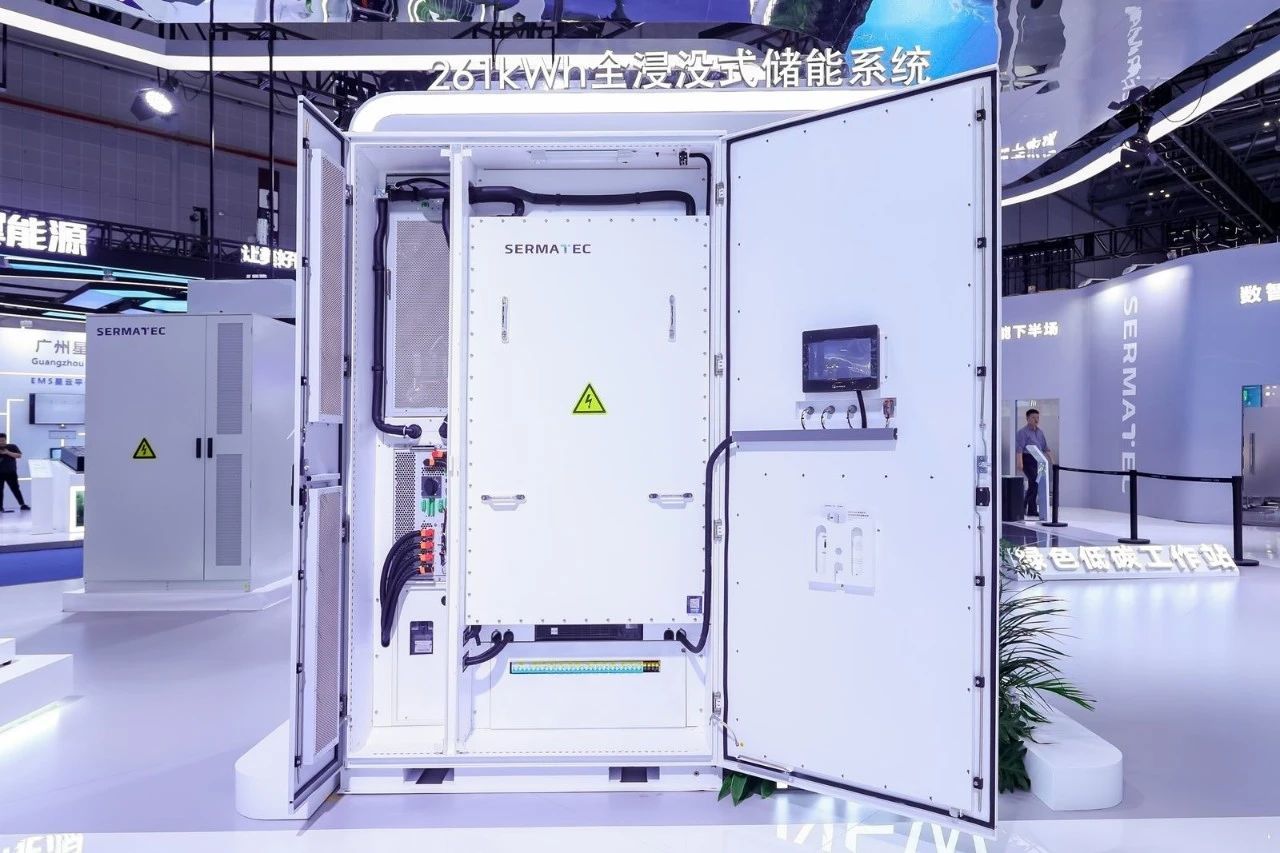

Sermatec Energy 261KWh fully submerged commercial storage: leading the way in new energy storage with inherent safety

2024-09-13 20:13

As the economic benefits of industrial and commercial energy storage become increasingly prominent and installed capacity surges, energy storage safety has become a focus of widespread concern both inside and outside the industry.

Sermatec Energy leads the field of new energy storage. As early as the beginning of this month, it took the lead in launching the 261 fully immersed liquid-cooled outdoor cabinet. With its efficient and reliable all-round three-dimensional heat dissipation performance of battery cells, it provides an innovative solution to the thermal management problems of industrial and commercial energy storage.

Protecting intrinsic safety and reducing life cycle costs

With the frequent charging and discharging of industrial and commercial energy storage projects, and their participation in grid response and ancillary services, their utilization rate has increased significantly. Domestic energy storage products will face real market "test" in the future.

Energy storage accidents are mostly caused by thermal runaway of batteries, which are sensitive to temperature and have concerns about adaptability, safety, and stability. Industrial and commercial scenarios have higher safety requirements due to the dense population, so it is urgent to develop a zero-risk, intrinsically safe energy storage system.

Sermatec Energy's 261KWh fully submerged industrial and commercial integrated cabinet was officially unveiled at the beginning of this month. With its efficient and reliable all-round three-dimensional heat dissipation performance of the battery cells, it will become a powerful tool to solve the current industrial and commercial energy storage thermal management problems!

Compared with the current industry, energy storage thermal management mainly adopts two technical routes: air cooling and liquid cooling, and there are disadvantages such as low cooling efficiency and uneven battery heat dissipation. Immersion liquid cooling technology is a technology that immerses all battery cells in special liquid for complete contact heat dissipation, which has higher heat dissipation efficiency, is more stable and safer.

At present, there are not many energy storage manufacturers in China that are engaged in immersion liquid cooling solutions. The main reason is that the research and development of high-performance and stable thermal conductive materials and overall product design is difficult and requires very high scientific research capabilities and financial guarantees. However, Sermatec Energy has successfully achieved a technological breakthrough in fully immersed energy storage products based on its fully self-developed and fully proprietary development model and years of energy storage application practice.

The fully submerged industrial and commercial integrated cabinet released by Sermatec Energy this time uses a new type of high-reliability composite thermal management material, which not only has ultra-high thermal conductivity, but also has excellent fire safety and dielectric properties. And considering the current green and sustainable development, the product uses an environmentally friendly biodegradable coolant with low ODP and GWP values and no greenhouse effect. It is not only environmentally friendly but also lower in cost, matching the current energy storage cost reduction needs. In actual applications, the battery is three-dimensionally coated with immersion liquid, which not only achieves true intrinsic safety, but also controls the surface temperature difference of the battery cell from the industry's common 6°C to 8°C to ≤2°C!

Taking into account the sealing issue that the industry is most concerned about immersion liquid cooling, Sermatec Energy's cabinet adopts a left and right compartment partition design to isolate the electrical compartment and the battery compartment, with front and back doors. The entire cabinet meets the IP54 waterproof and C4 anti-corrosion levels, and the energy storage unit adopts a fully sealed design to meet the ultra-high protection level of IP68!

It is not only a safety issue, but uneven heat dissipation will also cause different capacity attenuation rates between batteries, affecting battery life. Sermatec Energy products are equipped with a new intelligent and efficient thermal management system based on battery cells and demand-based BMS linkage, which can be intelligently adjusted to achieve precise temperature control. It also uses a self-developed BMS with EIS-enabled battery cell monitoring function, which can monitor the battery cell SOH online. It is reported that the current cycle life of the industry's energy storage system is about 70%-80% of the cycle life of a single battery cell. The fully immersed thermal management solution of Sermatec Energy can increase this number to 100%. The overall energy storage system achieves the same lifespan as the battery cell, achieving a reduction in cost over the entire life cycle!

At present, this fully immersed energy storage product has successfully passed the needle puncture thermal runaway test and its safety has been certified.

It is worth mentioning that the fully immersed industrial and commercial integrated cabinet does not require reserved heat dissipation channels and does not require rack-level connection harnesses, which greatly saves the floor space of industrial and commercial energy storage projects, making the overall cost controllable while greatly improving safety and economy!

The Ultimate Solution to Energy Storage Safety—System-Level Prevention

In fact, energy storage projects are complex systems that cover a wide range of disciplines, including HVAC temperature control, power industry, and mechanical automation, and involve the coordinated deployment of multiple levels, including battery cell materials, circuit structure, and software operation and maintenance. Therefore, energy storage safety cannot be guaranteed by simply doing a good job of temperature control.

At present, energy storage power stations still have many safety issues. The reason is that the scene conditions lead to dirty and blocked devices, electrical arcing, compressor downtime, control board failure, and ultimately thermal management failure. Sermatec Energy, which continues to make breakthroughs in the energy storage market, has achieved a six-layer safety design in three aspects: intrinsic safety, passive safety, and active safety, and truly realized a systematic and multi-dimensional guarantee of energy storage safety.

At the source of the energy storage system, Sermatec Energy chooses safer high-strength ceramic diaphragm lithium battery cells. This diaphragm is closely bonded to the matrix after being treated with a special process. Its high temperature resistance is significantly improved, and its melting point is relatively high. The temperature is 9°C before uncoating, and the heat shrinkage resistance and puncture resistance are higher. The same separator thickness achieves higher battery safety performance, and can also avoid affecting the charge, discharge, cycle efficiency and other properties of lithium batteries.

Secondly, early monitoring of thermal runaway from the cell level is a more effective and more difficult technology for safety prevention and control. Sending out early warning signals faster than before an accident occurs is of breakthrough significance for solving the safety of electrochemical energy storage.

As an energy digitalization operator with many years of R&D experience, Sermatec Energy has achieved perfection in this regard. In terms of intelligent internal short-circuit detection at the cell level, Sermatec Energy can accurately identify and quickly trigger a short-circuit warning inside the cell within 10 seconds.

The MOFS algorithm box independently developed by Sermatec Energy uses multi-source transfer learning to develop a thermal runaway early warning solution. Its algorithm fully utilizes thermal runaway case data from various battery types and under multiple operating conditions. It achieves lossless early warning of thermal runaway based on early signs of signals such as voltage, temperature, current, and impedance. Its related software and hardware have not only been fully verified under abuse conditions, but have also achieved normal operation in large-scale energy storage projects.

In addition, Sermatec Energy is also conducting further research and development to achieve early warning of micro-damage of energy storage batteries through analysis of the internal expansion force and composite gas of the battery cells.

Of course, the safety of energy storage products is not only about the preliminary design. Not long ago, a US energy storage battery container overturned and caught fire during transportation, causing the highway to be closed for dozens of hours, which once again triggered discussions in the industry about the safety of lithium batteries. In response, Sermatec Energy conducted a drop test on the battery packs before the products left the factory, using standards far higher than the industry's standards and simulating harsh usage scenarios to verify product quality. None of the battery packs used in the test caught fire.

However, there is no absolute safety in any industry, and electrochemical energy storage cannot guarantee 100% freedom from accidents. While minimizing the probability of accidents, Sermatec Energy uses a zoning and compartment isolation design, as well as 3-level active shutdown protection and 3-level passive isolation protection, to more accurately and comprehensively achieve comprehensive protection of the energy storage system!

Chasing rabbits, they compete for the first place; grabbing deer, they compete for opportunities.

The energy storage field is currently in a period of rapid development, showing its broad prospects for application and huge market potential. Tens of thousands of energy storage companies are established every year, and cross-border players are also flocking in, resulting in a mixed domestic energy storage market. Not every manufacturer can make a large investment in safety costs and technology research and development funds to ensure the quality of energy storage products.

At present, there are tens of thousands of energy storage system integrators in China, but after the test of time, the market will lead to safer and more reliable products. Sermatec Energy, with its "digital intelligence" technology reserves and self-developed advantages, has not only created many "first" and "first" achievements in the field of energy storage, but will also focus on the mission of "digital intelligence green energy, empowering a better life" in the future, focusing on the research and development of energy storage technology, and is committed to improving the safety and stability of energy storage systems and providing comprehensive energy storage solutions. It continues to lead the development trend of energy storage technology and the market, and bring more reliable cutting-edge energy storage products to the market.

Source: Polaris Energy Storage Network